What is a Prism Sheet?

A prism sheet is a thin optical component that adjusts the light coming from the back light unit (BLU) located behind the panel and directs it to the front of the panel.

Transforming LED Point Light Source to Surface Light Source: The initial light source from the LED is a point light source. This point light is scattered according to the fine patterns on the prism sheet. The scattered light is uniformly distributed across the entire display panel, creating a consistent image without dark areas.

Enhancing Brightness: The light formed by the back light unit is refracted in a specific direction, resulting in a display with higher brightness.

Structure of Prism Sheet and Back light Unit

The structure of the prism sheet reduces the light emitted in directions other than the front, narrows the viewing angle, and increases the brightness in the front direction of the back light emission surface.

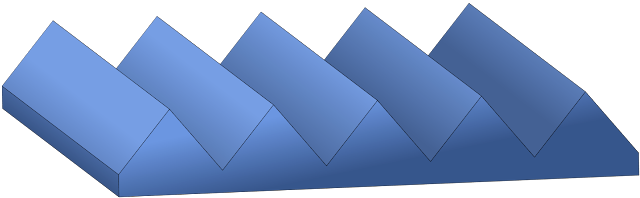

The following illustrates the structure of the prism sheet.

Figure 1 shows a single-layer prism sheet. The white areas represent air, while the blue parts are polymers with a relatively higher refractive index, such as PET.

A single layer of the prism sheet is not used alone; generally, composite structures like those shown in Figures 2 and 3 are used. Additionally, a diffusion sheet is added below Figures 2 and 3, creating a composite sheet from multiple sheets.

- Figure 2: Multiple prism sheets stacked in a package-on-package (POP) structure.

- Figure 3: Integrated structure of prism sheet and lens (integration of organic and inorganic materials).

By recalling the simple Snell's law learned in general physics, we can understand how the structure of the prism sheet uniformly disperses the light formed by the back light unit and improves the efficiency of the light.

Figure 4 is a simple illustration of the back light unit structure.

|

| Figure 4. Back light Unit |

- LED Light Source: The actual light-emitting source.

- Reflection Sheet: Made of materials with high reflectivity like silver or aluminum to reflect the light from the LED light source outward, preventing light loss below the panel.

- Light Guide Plate (Figure 5): The LED light has strong straightness, so it needs to be somewhat diffused to be uniformly distributed across the entire display. As shown in the light guide plate in Figure 4, the light is diffused along the engraved lines, evenly spreading the light across the screen. It is generally made of PMMA material.

- Diffusion Sheet: Scatters the light coming from the light guide plate.

- Prism Sheet: The light from the LED source enters the prism sheet. The prism sheet has a triangular structure and a medium with a high refractive index, reflecting a significant amount of photons back towards the light source. Photons reflected to the light guide plate are also recycled by reflecting them through the reflection sheet with high reflectivity.

The refractive index of polymers is relatively higher than the refractive index of air (1). Thus, depending on the angle of incidence, some light will undergo total internal reflection, while some will be transmitted. The periodic slope structure of the prism sheet reflects the light received from the light source back for recycling. Therefore, the structure of the prism sheet reduces light emitted in directions other than the front and narrows the viewing angle, increasing the brightness in the front direction of the back light emission surface.

.png) |

| Figure 5. Light Guide Sheet (Light Guide Plate) |

Are Prism Sheets Not Used in OLEDs?

Prism sheets are not used in OLEDs because OLEDs do not have a back light unit.

As mentioned at the beginning of this document, the roles of the prism sheet are as follows:

- Transforming LED point light source to surface light source

- Enhancing brightness

In other words, the prism sheet spreads the light coming from the LED light source and increases the brightness. However, since each pixel in an OLED emits its own light, there is no need for a back light unit.

However, recent attempts have been made to use optical sheets to improve the lower brightness and reduce burn-in phenomena compared to LCDs. But if optical sheets are used in OLEDs, the design process may become more complex, potentially making the device thicker and increasing costs. Additionally, the added layers that light must pass through could decrease the overall display brightness.

Refractive Index and Transmittance Determined by Material Properties

The refractive index of a medium is not a fixed value. Even when using the same medium, the refractive index varies with the wavelength of the electromagnetic wave passing through it. The shorter the wavelength passing through the medium, the more interference it encounters, increasing the refractive index as the frequency increases. Therefore, prism sheets must be made with materials and structures that consider various refractive indices within the visible light range (400-800 nm).

From the structure of the prism sheet described above, we can predict that the higher the refractive index of the material constituting the prism sheet, the greater the amount of recycled photons.

Additionally, materials with good durability are needed to ensure that the optical properties do not degrade over prolonged use, avoiding issues like yellowing and increased optical haze caused by changes in material properties due to the LED light source.

1 comment:

좋은 글 잘 봤습니다.

Post a Comment